Tunnel Oven for Annealing Bearing Rings

FEATURES

| Heating Method: | electric resistance heating |

| Chamber Dimensions: | 800 x 800 x 25.000 mm |

| Max. Operating Temperature: | 950 °C |

| Thermal Insulation: | ceramic fibres combined with fireclay lining |

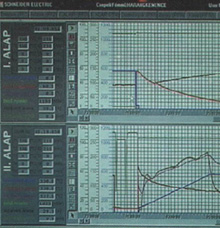

| Controls: | PLC, industrial PC, with an automatic cycle |

| Data Logging: | Industrial computer with comprehensive data logging |

| Heat Treatment Process: | annealing bearing rings after forging |

DESCRIPTION

This is a directly heated tunnel oven that is designed for continuous operation and cars (i.e. a car bottom) of a high load capacity to move the charge through 5 heating zones. Each zone has a fan to ensure improved heat transfer. The batches of products are put in baskets to be placed on the cars. The cars are then gradually moved through the different temperature zones from the inlet to the outlet of the oven.

APPLICATIONS

Stress-relief annealing of mass-produced parts, machine components and structures made of alloyed and non-alloyed steel.

BUYING CRITERIA

Dimensions and weight of products, annealing temperature, temperature accuracy requirement, other process parameters (heating-up and cooling times, etc.).

NOTES

The two ovens had to be designed, manufactured and installed in lieu of the client’s old ovens, while the existing rails and carriages had to remain in place and be renewed with the same functionality.

Click here to download the product sheet (pdf)

Click here to download the product sheet (pdf)

For the latest version of the free Adobe Acrobat Reader® to view the pdf click here.

OUR MAIN ACTIVITIES

Our core business is the manufacture of industrial furnaces and thermal process equipment in accordance with the customer’s process specifications and technical requirements.

We provide troubleshooting, regular or occasional maintenance, as well as the renewal and upgrade of industrial furnaces.

Our company has gained a lot of experience in the construction of steel structures. We ourselves do minor cutting works, while, for doing large-scale ones, we cooperate with highly experienced professional companies.

We undertake the annealing and stress relieving heat treatment of large and heavy workpieces in the furnace.