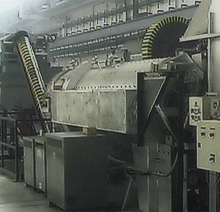

Rotary Drum Heat Treatment Line with a Protective Atmosphere and Indirect Heating for Hardening Balls and Rollers

FEATURES

| Heating Method: | Electric resistance heating |

| Max. Operating Temperature: | 800 x 800 x 25.000 mm |

| Tempering Furnace: | 950 °C |

| Thermal Insulation: | ceramic fibres |

| Controls: | automatic, PLC, PC, thyristor power control |

| Data Logging: | computerised, with continuous documentation |

| Heat Treatment Process: | hardening and tempering of bearing balls and rollers |

DESCRIPTION

Components of the continuous operation heat treatment line:

- weigher and feeder

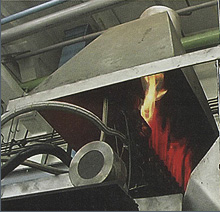

- rotary retort hardening furnace with a protective atmosphere

- oil hardening vat (heatable and coolable)

- washing unit

- rotary retort tempering furnace

- discharge unit

APPLICATION

The hardening and tempering of balls and rollers of rolling-contact bearings. Particularly suitable for heat-treating small-size mass produced parts (case hardening (carburising), temper-hardening). The atmosphere that is used for protection is endogas (a gas atmosphere that prevents oxidation and decarbonisation). With an appropriate protective atmosphere, in-line carburisation is also possible.

BUYING CRITERIA

The dimensions, weight and quantity of parts and target parameters of the heat treatment proces.

NOTES

The system was purchased second-hand and shipped flame-cut from the US (without any documents or empty electrical cabinets). The difference between the European and US (3 × 270 V, 60 Hz) power supply systems meant that the 460 kW power system needed a major conversion. The entire control system was upgraded and integrated with all the line units.

The gas supply system underwent a major modification.

A new external cooling unit was designed and manufactured.

OUR MAIN ACTIVITIES

Our core business is the manufacture of industrial furnaces and thermal process equipment in accordance with the customer’s process specifications and technical requirements.

We provide troubleshooting, regular or occasional maintenance, as well as the renewal and upgrade of industrial furnaces.

Our company has gained a lot of experience in the construction of steel structures. We ourselves do minor cutting works, while, for doing large-scale ones, we cooperate with highly experienced professional companies.

We undertake the annealing and stress relieving heat treatment of large and heavy workpieces in the furnace.